L Bolt

L Bolt Specification

- Thickness

- 10 mm

- Dimension (L*W*H)

- Custom as per requirement

- Head Type

- L-Type

- Length

- 100 mm to 1500 mm

- Surface Treatment

- Polished, Zinc Plated, Hot Dip Galvanized

- Heat Treatment

- Quenched & Tempered

- Diameter

- 10 mm to 32 mm

- Thread Type

- Full Threaded

- Standard

- DIN 3570 / IS Standards

- Grade

- SS304, SS316, MS, GI

- Use

- Industrial Machinery, Construction Fittings

- MOQ

- As per customer requirement

- Tensile Strength

- High Tensile

- Corrosion Resistance

- Yes

- Packing Type

- Bag, Box, Gunny Sack

- Application

- Foundation Bolts, Supporting Pipework, Structural Fastening

- Material

- Stainless Steel, Mild Steel, Galvanized Iron

- Color

- Silver, Natural Finish

About L Bolt

Features:

- Sturdy construction

- Excellent strength

- Anti-corrosive nature

Engineered for Strength and Versatility

Our L Bolts undergo advanced heat treatment, achieving exceptional tensile strength ideal for heavy-duty use in industrial machinery and construction fittings. Custom sizing and reliable full threading guarantee precision and stability in any installation, providing security even in challenging environments.

Outstanding Corrosion Resistance

Manufactured from top-grade Stainless Steel, Mild Steel, or Galvanized Iron, these L Bolts withstand harsh conditions through specialized surface treatments such as polishing, zinc plating, and hot-dip galvanizing. Their corrosion-resistant properties protect against environmental damage, making them suitable for outdoor and industrial applications.

Tailored to Your Requirements

We offer L Bolts in a range of diameters (10 mm to 32 mm) and lengths (100 mm to 1500 mm) to match unique project needs. Minimum order quantities and packaging (bag, box, or gunny sack) can be customized, ensuring each consignment fits your specifications perfectly.

FAQs of L Bolt:

Q: How are stainless steel and galvanized L bolts different in terms of corrosion resistance?

A: Stainless steel L bolts, particularly grades SS304 and SS316, provide superior corrosion resistance ideal for environments exposed to moisture or chemicals. Galvanized options are coated to resist rust and are cost-effective for less aggressive environments, though not as enduring as stainless steel in highly corrosive conditions.Q: What is the process for customizing L bolts according to my project requirements?

A: You can specify dimensions such as diameter, length, and thickness based on your applications needs. We manufacture according to DIN 3570 or IS standards, and offer surface treatments like polishing, zinc plating, or hot-dip galvanizing. Packing and minimum order quantities are tailored as per customer requirement.Q: When should I choose high tensile L bolts for my construction or industrial application?

A: High tensile L bolts are recommended when your project demands increased strength and load-bearing capacity, such as in structural fittings or the support of heavy machinery. Their heat-treated, quenched, and tempered properties ensure optimal performance under stress.Q: Where are L type bolts commonly used?

A: L type bolts are widely utilized in foundation bolting, supporting pipework, anchoring structural steel, and securing industrial machinery. Their shape and strength make them ideal for both concrete fastening and heavy-duty construction projects.Q: What benefits do full threaded L bolts offer for installations?

A: Full threaded L bolts allow for flexible adjustment and secure fastening over longer lengths, providing enhanced grip and ensuring better load distribution in concrete, structural, or foundation applications.Q: Can these L bolts be used in both indoor and outdoor settings?

A: Yes, thanks to their corrosion-resistant materials and various surface treatments, these L bolts are well-suited for both indoor mechanical installations and outdoor construction environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Structural Bolts Category

Hex Head Threaded Bolts

Standard : DIN 933, ISO 4017, BS 3692, ASTM, JIS, IS

Head Type : Other, Hex Head

Length : 10mm to 500mm or as specified

Use : Industrial, construction, machinery assembly, automotive

Heat Treatment : Other, Case Hardened, Quenched and Tempered, as per grade

Diameter : M6 to M64 or 1/4 to 2 1/2

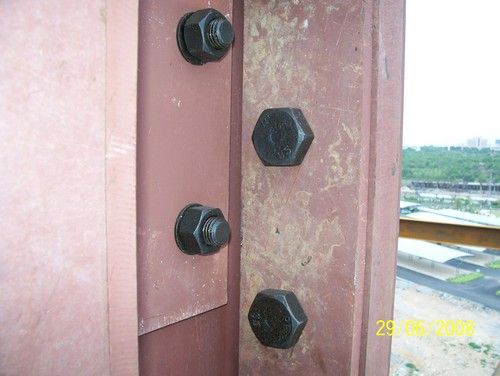

HSFG Bolts

Standard : EN 143994

Head Type : Other, Hex Head

Length : 50mm

Use : Structural Connections

Heat Treatment : Other, Quenched and Tempered

Diameter : M16

Galvanised Bolts

Standard : ISO 4017

Head Type : Other, Hex

Length : 30 mm

Use : Structural applications

Heat Treatment : Tempered

Diameter : M10

OHE Bolt

Standard : DIN 3570

Head Type : Other, Hex Nut

Length : 200mm

Use : Overhead Equipment

Heat Treatment : Other, Quenched and Tempered

Diameter : 12mm

Send Inquiry

Send Inquiry